uses of rockwell hardness test|rockwell hardness c scale chart : distribution The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied . WEBAgora - 29° / Sensação - 30°. Esteja preparado para passar o final de semana em Iturama - MG! Confira a previsão do tempo detalhada na Climatempo, com informações de clima e muito mais!

{plog:ftitle_list}

WEBPorteiro procura Sexo casual com coroas e mulheres ou casais. 2,092 baixinhas gostosas coroas FREE videos found on XVIDEOS for this search.

Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the .What is the Rockwell Hardness Test? Rockwell Hardness Test Procedure: A Step-by-Step Guide. How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness . Rockwell superficial scales use lower loads than a regular Rockwell test and are used to test materials too thin or small for the regular scales or outside the normal ranges. .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject.Advantages and disadvantages of hardness testing using the Rockwell method. The Rockwell method offers the following advantages: No specimen preparation required (cutting, grinding, embedding) Direct reading of the hardness value; .The Rockwell hardness test at a glance: Generally used for larger samples. No optical readout. Can be used for advanced tests. Standards: ASTM E18, ISO 6508 and JIS Z 2245. See our complete range of Rockwell hardness testing . Being the most cost-effective method, the Rockwell Hardness test is widely employed for measuring indentation hardness. How it works. The Rockwell Hardness test uses a conical diamond or a hard steel ball as an .

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. .Conducting a hardness test using the Rockwell hardness method can be difficult, especially if you misunderstand its principles and application. Not to overstate it, but without an understanding of the Rockwell hardness method, you might end up going round in circles or, worse still, end up with an inaccurate material hardness value.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). .The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .

The Rockwell hardness test is widely used to standardize the hardness of metals. Although it is possible and easy to perform, it can be time-consuming and expensive. It is also important to note that since the hardness of a material is determined by the Rockwell Hardness number, it doesn’t indicate whether the material with that number will .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products. Applications for Rockwell Methods The Rockwell hardness test is widely used in various industrial

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.

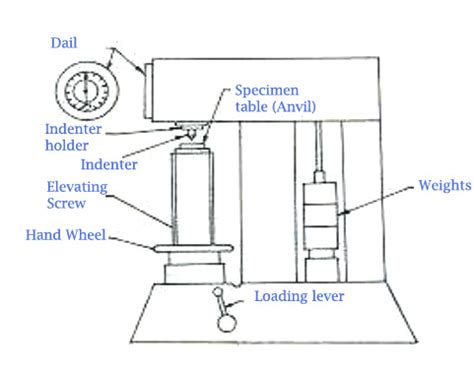

rockwell hardness tester diagram

You can use the Rockwell hardness test to test the hardness of materials. You will use the Rockwell test to perform tests on metals ranging from thin steel all the way to harder metals like Titanium. However, there are multiple scales to test in and these are identified by a letter ranging from A-V Each scale uses a different indenter and load to perform the test.A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

Foremost to any Rockwell test process is identification of the proper hardness scale to be used on the component to be tested. There are 30 different Rockwell scales with the majority of applications covered by the Rockwell HRC and HRB scales for testing most steels, brass, and other metals.The Rockwell hardness test uses a diamond cone or steel ball indenter to make an indentation in the material being tested. The depth of the indentation is measured and used to calculate the Rockwell hardness number (RHN) of the material. There are several different Rockwell scales, each designed for specific types of materials and applications. .To accommodate the hardness testing of this diverse range, several different indenter types are used in the Rockwell hardness testing along with a range of standard force levels. Each combination of indenter type and applied force levels has been defined using a distinct Rockwell hardness scale. As per ASTM E 18, there are thirty (30) different .The Rockwell hardness test has a variety of applications. It is not only used to determine material properties according to hardness and forming processes, but also for quick and effective testing in production and incoming goods departments. This helps ensure that the material meets specified requirements and will behave optimally when used .

The RockGen Rockwell Hardness Testing System was designed to test the hardness level of metal based on the indentation they leave on a tested material according to the Rockwell scale. The machine is capable of . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform and more accurate than other hardness methods. The Rockwell test .In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. The Rockwell hardness of the test piece is calculated by subtracting .

Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. Rockwell invented the Rockwell hardness test. As a metallurgist for a large ball bearing company, he wanted a fast, nondestructive .The Rockwell hardness test uses a simple mechanical load application, while the Vickers hardness test uses an optical measurement method. The Rockwell hardness test is the most common type of hardness testing method because it is easier to perform and more accurate than other methods.Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).

rockwell hardness test diagram

Every Rockwell hardness scale is identified by a letter signifying the indenter type and the two loads used for the test. A Rockwell hardness number is a combination of the numerical hardness value and the letter for the scale preceded by the letters, HR. For instance, a hardness value of 80 on the Rockwell A scale is denoted as 80 HRA. .The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional examinations in the sequence. Process The Rockwell Hardness test and its counterparts [.] The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of the indentation as the force on the .It’s most commonly used to check the hardness of steel that’s been heat treated. Here’s the process: How to Use a Rockwell Testing Machine. Pick out the penetrator. Usually soft materials like 1018 mild steel will use the Rockwell B scale, which makes use of a 1/16″ rounded steel penetrator with a 100 Kg major load.

Here's a step-by-step instruction to guide you through a standard hardness testing procedure, in this case, we'll use the commonly used Rockwell hardness testing method as our guide: Selection of an appropriate scale: Different testing scales (e.g., Rockwell B or C, etc.) are designed for materials of varying hardness. The test's success is .

The most common methods used for testing the hardness of metals are Rockwell, Brinell, Vickers, and Knoop. . Micro hardness testing uses high magnification to accurately measure the dimensions of the small indentation. The test indentation is examined and measured using a microscope or an optical system. In macro hardness testing, the .

rockwell hardness test calculation

rockwell hardness scale explained

Resultado da 15 de mar. de 2023 · ? kiff (series) 111; Character? mary buns 4; Artist? mr valentine00 378; General? bathroom 30645? blue fur 93577? breasts .

uses of rockwell hardness test|rockwell hardness c scale chart